About Beechcraft PU Moulding

Beechcraft PU Moulding and Design have over 50 years’ experience in producing custom enclosures and mouldings from rigid structural Polyurethane. We specialise in producing low volume, high quality mouldings from low-cost tooling with rapid turnaround from ‘Concept to Reality’

Why Choose Polyurethane?

- Tough, Rigid Mouldings

- Cost-Effective Low-Volume Production

- Excellent Strength-to-Weight Ratio

- Design Flexibility

- Durable and Long-Lasting

- Customisable Finishes

What is it?

Our Polyurethane is a rigid self-skinning expanded foam system specifically blended to produce tough rigid and structural mouldings to a high specification.

What is it good for?

Low-run batch quantities of mouldings for electronics enclosures and devices that benefit from varying wall sections from 1.5 – 40mm locally that can create an integral chassis in conjunction with strength and aesthetics. It is an excellent material for handheld devices or those requiring the benefits of the material’s excellent insulation properties or buoyancy.

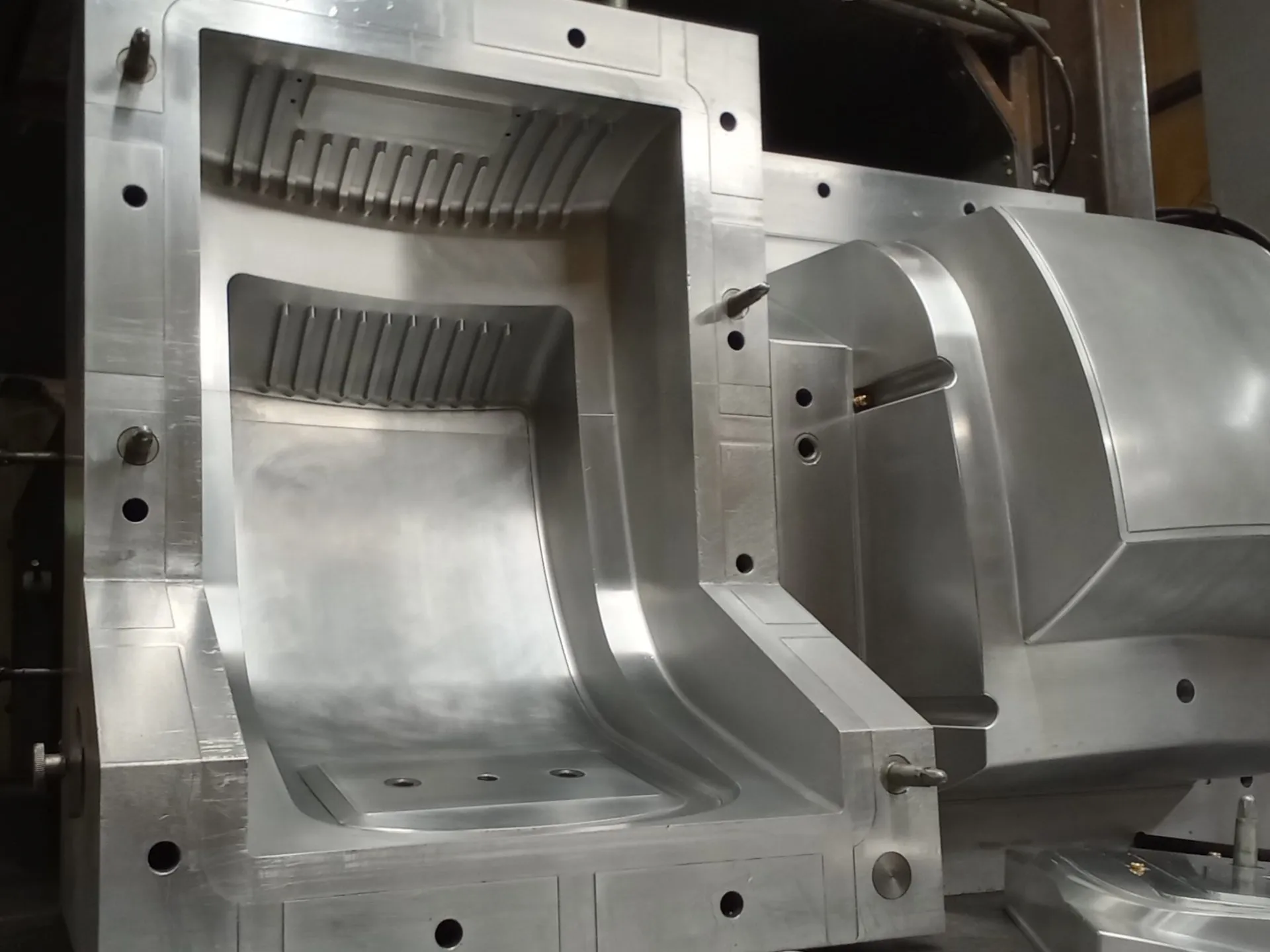

What is the Process?

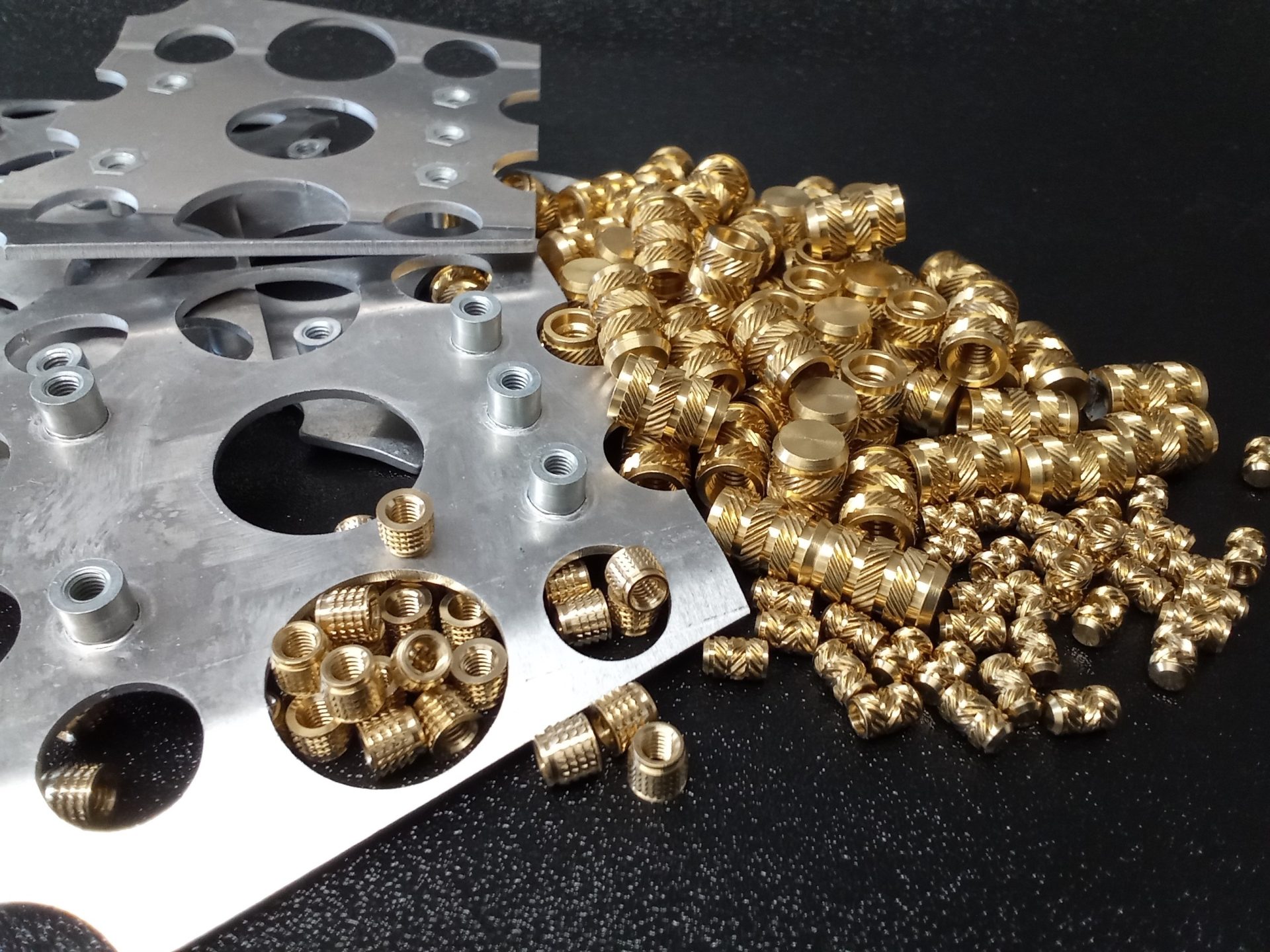

Reactive Injection Moulding (RIM) is an Iso / Polyol blend which is injected under low pressure into a closed aluminium mould. The mixture expands rapidly expelling air from the cavity, filling the mould tool with a rigid structural polyurethane that consists of a hard outer skin with softer inner core, giving an average density of 600-650 kg/m3 ( on a typical 6mm wall section).

Why is it Cost Effective?

If your requirements are 20-1,500 units per annum and your project has a high intrinsic value, this is the process for you.

Mouldings are exceptionally durable and can last decades. Its strength and rigidity mean far fewer breakages than other similar processes.

Product Design

Tooling

Materials & Finishes

We offer a variety of Materials & Finishes to give your product the perfect balance of functionality and aesthetics. From structural integrity to surface treatments, our materials and finishing options are designed to meet your specific needs.